Alimak Elevator Parts: The Backbone of Industrial Vertical Transport

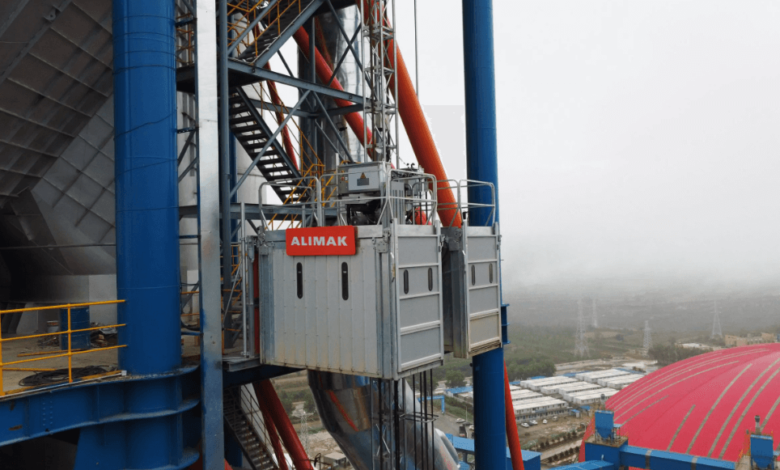

In high-stakes industrial environments, elevators are not merely a convenience—they are a lifeline. Whether on towering construction sites, deep within mining shafts, or stationed on offshore oil rigs, vertical transportation plays a critical role in maintaining operations. Among the leading names in the vertical transport industry, Alimak has carved out a reputation for reliability, engineering excellence, and durability. But even the most advanced elevator systems require proper maintenance, and at the heart of this lies a deep understanding of Alimak elevator parts.

This article explores the essential components of Alimak elevators, their role in ensuring uninterrupted operations, and why sourcing the right parts is crucial for safety, efficiency, and long-term cost savings.

What Makes Alimak Elevators Unique?

Founded in Sweden, Alimak has been delivering high-performance elevators and hoists for over 70 years. These systems are built on a rack-and-pinion drive mechanism, which offers greater control and adaptability for industrial applications compared to conventional cable-driven elevators.

Alimak’s design is tailored for rugged environments where space, weight capacity, and weather resistance are key. Used across construction, mining, energy, and marine industries, their vertical access solutions are trusted globally. However, regular operation in harsh conditions inevitably leads to wear and tear—making high-quality alimak elevator parts indispensable for routine maintenance and emergency repair.

See aslo: The Role of Adverse Media Checks in AML Compliance Programs

The Crucial Role of Alimak Elevator Parts

Alimak elevator parts are engineered to support extreme conditions, ranging from high heat and dust in cement plants to corrosive salty air on offshore platforms. These parts are not generic; they are precision-manufactured to fit specific Alimak models such as the SCANDO series, SE, or HEK.

Using substandard or non-OEM parts can compromise the safety and efficiency of the entire elevator system. The choice of replacement parts should never be taken lightly, as the risks associated with mechanical failure can include equipment damage, site shutdowns, or even life-threatening accidents.

Key Categories of Alimak Elevator Parts

Understanding the various categories of Alimak elevator components helps operators and maintenance personnel make informed decisions when ordering replacements.

1. Drive Mechanism Components

These parts convert motor power into vertical motion.

- Pinion gears

- Rack segments

- Motor coupling units

- Drive shafts and bearings

These elements work together to propel the elevator safely and smoothly. Failure in any of these parts can lead to jerky motion or complete system halt.

2. Braking System Parts

Given the vertical nature of the system, reliable brakes are essential to prevent free falls and control descent speeds.

- Brake calipers

- Brake pads

- Brake release handles

- Emergency arrest devices

3. Electrical and Control Parts

Modern Alimak elevators are equipped with intelligent electrical systems that regulate movement, monitor weight, and provide safety overrides.

- Control panels

- Limit switches

- Load sensors

- Relays and circuit breakers

- Wiring harnesses

Malfunctions in electrical systems can result in elevator downtime or incorrect responses to load conditions.

4. Cabin and Structural Components

These parts protect occupants and provide the structural integrity needed for daily use.

- Guide rollers

- Safety doors and interlocks

- Cabin frames

- Landing gates

Durable cabin parts reduce vibration, ensure user comfort, and maintain compliance with international elevator safety standards.

Common Signs Your Alimak Elevator Parts Need Replacement

Even with robust designs, Alimak elevators show signs of part degradation over time.

Unusual noises: Grinding or screeching often points to worn gears or bearings.

- Slower operation: Could indicate drive motor fatigue or gear wear.

- Faulty stops: Brakes or limit switches may need adjustment or replacement.

Industries That Depend on Alimak Elevator Parts

The diversity of industries using Alimak elevators highlights the need for adaptable and reliable spare parts:

🏗️ Construction Sites

High-rise developments require temporary hoists for transporting workers and materials. Frequent use calls for regular part replacements, particularly for doors, pinions, and safety locks.

⛏️ Mining Operations

Mines operate in dusty, abrasive, and often humid environments. Specialized electrical components and sealed control systems are vital for safety.

🛢️ Oil & Gas Platforms

Elevators in offshore settings face continuous exposure to salt and moisture. Anti-corrosion parts, sealed electrical systems, and robust brake assemblies are mandatory.

Future of Alimak Elevator Maintenance: Predictive Analytics

Today’s industrial elevators are becoming smarter, with built-in sensors that monitor part wear, motor temperature, load consistency, and electrical flow. This data is used to trigger predictive alerts when parts approach failure thresholds.

By integrating AI-based diagnostics and remote monitoring, operators can move from scheduled maintenance to need-based service—a transition that saves money and enhances safety.

Conclusion: Reliable Elevators Start With Reliable Parts

Alimak has earned its place as a trusted name in vertical transport, but even the strongest systems rely on their smallest components. Whether you’re managing a temporary construction hoist or a permanent lift on an oil rig, the performance of your elevator hinges on the quality of its components.

From brake pads to control systems, every component plays a critical role—and cutting corners is never worth the risk.